CNC manufacturing

CNC stands for Computer Numerical Control, which is being used in our company. In connection with machine tool, it can be used as a “Computer driven machining-tool”, which means a machining-tool that uses CNC management system in order to machine a product by the technological NC program used.

MCV 750 – 3-axis milling machine

- Highly effective machining ensured by the application of high-speed spindle and fast movement

- High rigidity of the supporting frame enables power machining as well as precise machining of complex components

- The linear axis dynamics enables a high-speed machining of forms

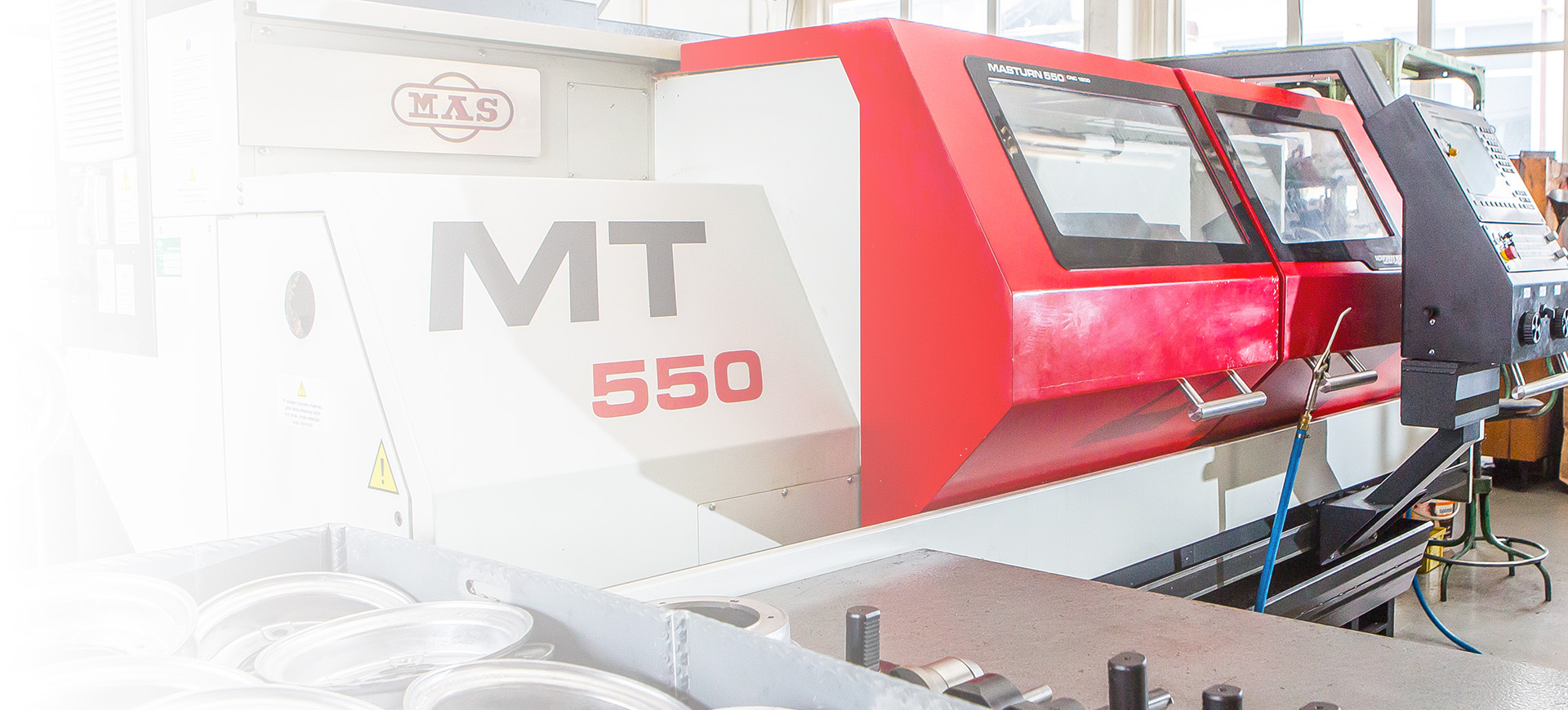

Masturn 550 – CNC lathe

- Simple machine suitable for unit and small series production

- High accuracy, performance, easy operation

- Constant cutting speed – High quality of machined product

- Graphical simulation of machining

- Machining is possible in manual mode like on a common lathe or in automatic cycle with CNC system support on an established cycle basis

- The program can be created by contour programming or DIN programming

- Cutting conditions and product shape entries are entered by keyboard into the management system and are automatically processed